To hit a cart with wires, carefully position the wires and swing them toward the cart to make contact. To achieve a successful hit, use the appropriate force and angle when swinging the wires to make sure they connect with the cart effectively.

Hitting a cart with wires can be a useful technique for various purposes, such as moving the cart or dislodging items. Whether you are working in a warehouse, conducting an experiment, or simply need to move a cart from one place to another, mastering the skill of hitting a cart with wires can be incredibly valuable.

We will explore the practical steps and tips to effectively hit a cart with wires, ensuring that you can accomplish your tasks with efficiency and precision. So, let’s delve into the details and learn how to hit a cart with wires like a pro.

Essential Steps For Hitting A Cart With Wires

Learn the essential steps for hitting a cart with wires. Follow these guidelines to achieve success and optimize your wire-hitting strategy. Mastering this technique can greatly enhance your efficiency and overall productivity.

Safety Precautions Before Starting

Before embarking on the task of hitting a cart with wires, it’s essential to prioritize safety precautions. Always wear appropriate safety gear, including gloves and goggles, to protect yourself from potential hazards. Additionally, ensure that the area where the cart is located is clear of any obstructions or bystanders to minimize risks during the process.

Understanding The Cart Anatomy

To effectively hit a cart with wires, you need to have a good understanding of the cart’s anatomy. Identify the key components of the cart, including the wheels, frame, and potential structural weaknesses. This knowledge will help you determine the most effective points of impact for the wires and ensure the desired outcome is achieved.

Necessary Tools For The Task

When preparing to hit a cart with wires, having the necessary tools at hand is crucial for a successful operation. Some of the essential tools required for this task include wire cutters, insulated gloves, a multimeter, and of course, a sufficient length of wires. Make sure these tools are in good working condition and readily accessible before getting started.

Preparing The Cart And Wires

Before you can hit a cart with wires, it is crucial to prepare both the cart and the wires to ensure a successful connection. This involves cleaning the cart contact points, stripping the wires correctly, and ensuring a strong connection for optimum performance.

Cleaning The Cart Contact Points

Cleaning the cart contact points is essential to establish a strong and reliable connection. Over time, dirt, rust, or debris can accumulate on the cart’s contact points, hindering the flow of electricity. Use a clean, dry cloth to wipe the contact points and remove any build-up. For stubborn debris, a small amount of contact cleaner can be used to ensure the surfaces are thoroughly clean.

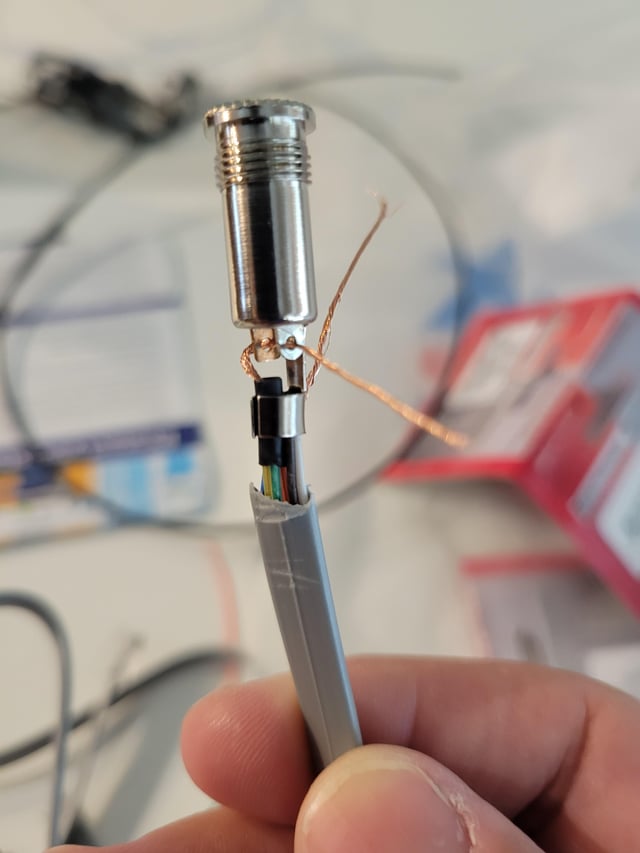

Stripping The Wires Correctly

Stripping the wires correctly is crucial to make a secure connection. Use a wire stripper to carefully and evenly remove the insulation from the end of the wires. Avoid stripping off too much of the wire, as this can compromise the connection. Aim to expose just enough of the copper conductor to create a solid connection with the cart.

Ensuring A Strong Connection

Once the wires are stripped, it is important to ensure a strong connection with the cart. Ensure that the exposed copper conductor makes direct contact with the cart’s contact points. Use insulated connectors or soldering to secure the wires in place and prevent any accidental disconnection during use. Performing a tug test can help verify the strength of the connection before proceeding further.

Tips To Maximize Success

When it comes to hitting a cart with wires, achieving success depends on various factors including the correct wire gauges for the task, efficient heat management, and testing connection stability. Here are some tips to maximize your success in accomplishing this task:

Correct Wire Gauges For The Task

Choosing the correct wire gauge is crucial for the success of hitting a cart with wires. Using a wire gauge that is too thin may result in overheating and potential damage, while a gauge that is too thick can be challenging to work with and can lead to inefficient heat distribution. Ideally, refer to the manufacturer’s guidelines or consult with a professional to select the appropriate wire gauge for the specific task at hand.

Heat Management During The Process

Effective heat management is vital when hitting a cart with wires. To prevent overheating and potential damage, ensure the wires are properly insulated and spaced apart. Additionally, consider using heat-resistant materials and employing adequate ventilation to dissipate excess heat. Regularly monitoring the temperature during the process is essential to avoid overheating and ensure a successful outcome.

Testing Connection Stability

Prior to finalizing the wire connections, thorough testing is essential to ensure their stability. Use a multimeter to verify the continuity and resistance of the connections. This step will help identify any potential issues or weak points in the connections, enabling you to address them before finalizing the setup. By testing the connection stability, you can instill confidence in the reliability of the wire connections, ultimately maximizing the success of hitting a cart with wires.

Avoiding Common Mistakes

When it comes to hitting a cart with wires, it’s crucial to avoid common mistakes that can lead to connection issues and maintenance setbacks. By understanding the potential pitfalls and taking proactive measures, you can ensure a smooth and efficient process for this task. Let’s explore some key strategies for avoiding common mistakes in wire connection to carts.

Identifying And Addressing Wire Compatibility Issues

Before hitting a cart with wires, it’s essential to identify and address any compatibility issues that may arise. One common mistake is overlooking the compatibility between the wire and the cart’s electrical system. By ensuring that the wire is compatible with the voltage and amperage requirements of the cart, you can prevent potential damage to the system and ensure a secure connection.

Overcoming Connection Setbacks

Connection setbacks can occur if proper attention is not given to the wiring process. One mistake to avoid is improper insulation and securing of connections, which can lead to electrical hazards and performance issues. By carefully following the manufacturer’s guidelines and using appropriate tools for secure connections, you can overcome common setbacks and ensure a reliable electrical connection for the cart.

Maintenance Tips For Longevity

Ensuring longevity and optimal performance of the wire connection requires regular maintenance. One common mistake is neglecting routine inspections and maintenance, which can lead to wiring degradation and potential safety hazards. Implementing a proactive maintenance schedule, including inspecting for wear and tear, tightening connections, and replacing worn-out components, will help prolong the lifespan of the wire connection and ensure continued reliability for the cart.

Troubleshooting And Fine-tuning

Troubleshooting and fine-tuning are crucial steps in ensuring that your wired cart system operates at its best. By diagnosing connectivity issues, adjusting wire placement for optimal performance, and knowing when to seek professional help, you can maximize the efficiency of your cart system. Let’s delve into each of these aspects to help you get the most out of your wired cart setup.

Diagnosing Connectivity Issues

If you are experiencing connectivity problems with your wired cart system, it’s essential to diagnose the issues accurately. Start by checking the connections at both ends of the wires. Ensure that the wires are securely plugged in and that there are no visible signs of damage. Use a multimeter to test for continuity and ensure that the wires are conducting electricity effectively. Additionally, inspect the connectors for any signs of corrosion or wear that might be affecting the signal.

Adjusting Wire Placement For Optimal Performance

Proper wire placement plays a significant role in the performance of your wired cart system. Ensure that the wires are routed away from potential sources of interference, such as power cables or other electronics. Use cable management tools to secure the wires and prevent them from becoming tangled or damaged. Conduct regular inspections to identify any areas where the wires may be pinched or compromised, and make necessary adjustments to ensure optimal performance.

When To Seek Professional Help

While troubleshooting and fine-tuning your wired cart system can address many issues, there are times when professional assistance is necessary. If you encounter persistent connectivity problems despite your best efforts, or if you are unsure about the best wire placement for your specific setup, it’s wise to seek the expertise of a professional. Professional technicians can conduct comprehensive assessments, identify underlying issues, and provide tailored solutions to ensure the smooth operation of your wired cart system.

Frequently Asked Questions Of How To Hit A Cart With Wires

What Are The Basic Tools Needed To Hit A Cart With Wires?

To hit a cart with wires, you will need wires, pliers, wire cutters, a cart, and safety gloves. These tools are essential for effectively hitting a cart with wires.

How Do I Ensure Safety While Hitting A Cart With Wires?

To ensure safety while hitting a cart with wires, always wear safety gloves and make sure the wires are properly insulated. Additionally, avoid touching the cart with bare hands and work in a well-ventilated area.

What Are The Potential Benefits Of Hitting A Cart With Wires?

Hitting a cart with wires can improve its efficiency, reduce rust, and enhance its durability. It also helps in maintaining the cart’s structural integrity and can prevent potential damage in the long run.

Conclusion

Thanks for reading our guide on hitting a cart with wires. By following these tips, you can safely and effectively achieve your goal. Remember to always prioritize safety, ensure proper grounding, and use the right tools. With practice and attention to detail, you’ll soon become a pro at hitting a cart with wires.

Happy wiring!